Service

What We Offer

Comprehensive CNC machining solutions

At Olige, we provide exceptional CNC machining services that exceed client expectations, helping businesses turn their visions into reality.

CNC Milling

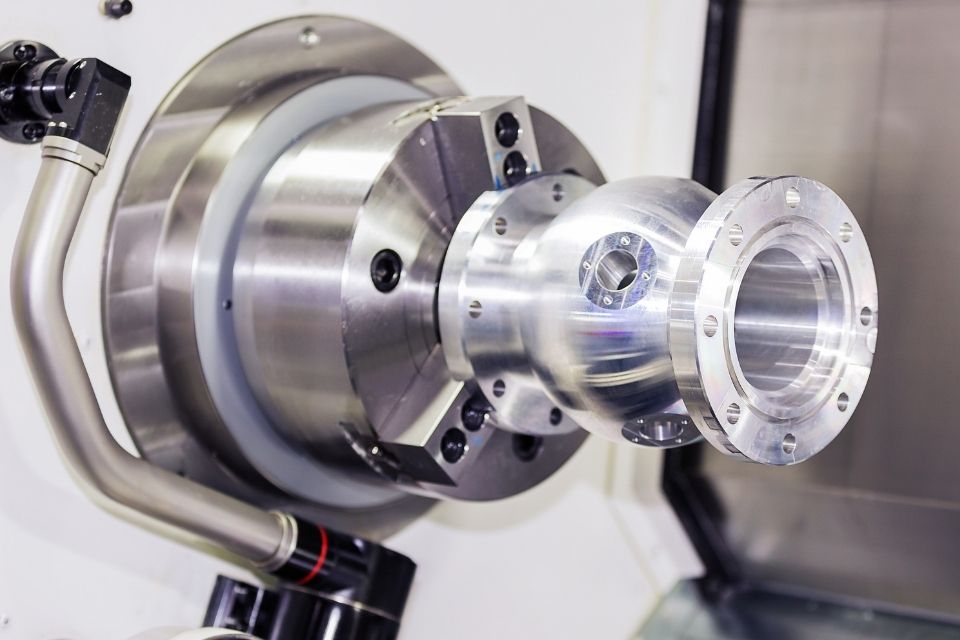

CNC Turning

Multi-axis Machining

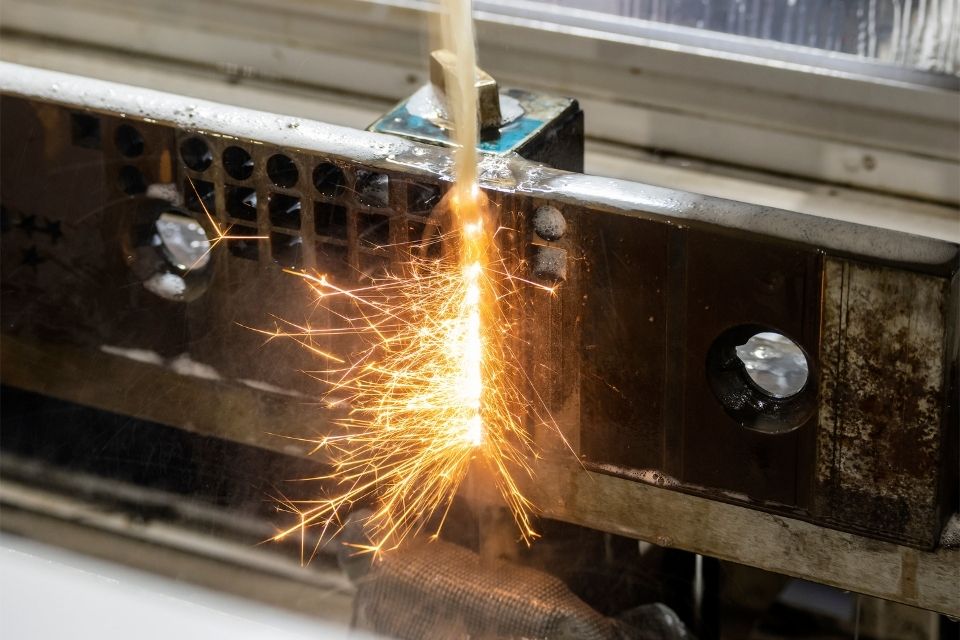

EDM Machining

Rapid Prototyping

Batch Production

Expertise

Our expertise

DFMA Feedback

We continuously provide free DFMA feedback so that your design is the best feasible design, and your project runs well.

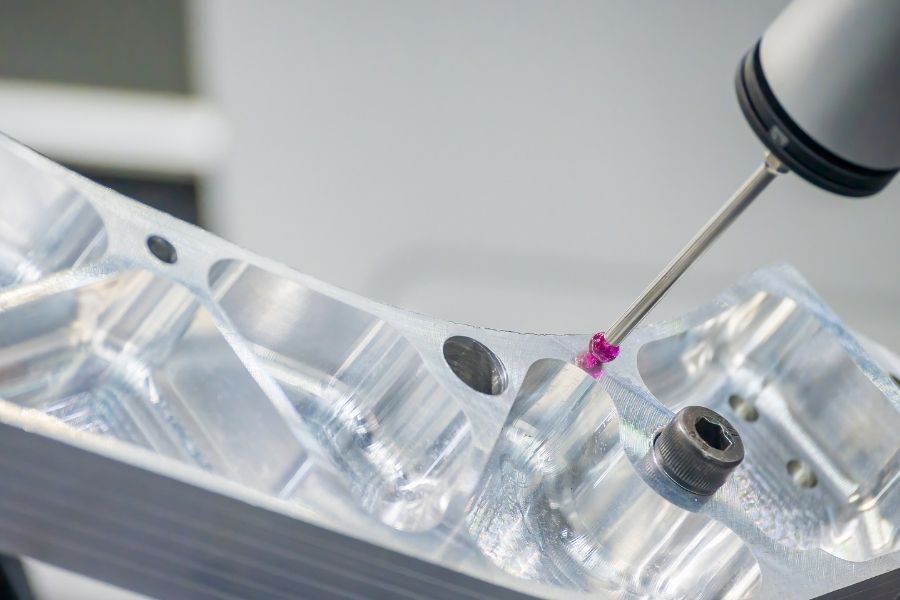

Quality Assurance

We rigorously test our products to ensure that they meet or exceed industry standards and customer expectations.

Customer Service

We understand the importance of clear communication and prompt response times, and we strive to exceed customer expectations in every interaction.

Why Us

Why trust us

Olige’s expertise in engineering and machining allows us to work with a diverse range of materials and projects, ensuring that we can meet the specific requirements of your project, regardless of the material type.

Expertise

Skilled professionals and advanced technology ensure precision and excellence.

Custom Solutions

From design to production, we provide end-to-end custom solutions that simplify your work.

Quality

ISO 9001 certification guarantees top-notch quality control and consistent results.

Customer Focus

Our focus on customer needs ensures a positive experience and successful outcomes.

Schedule service today and let us take care of all your needs.

Let’s turn your vision into reality with precision CNC machining, rapid prototyping, and reliable production services.

TESTIMONIAL

Client feedback & reviews

Welcome to leave any suggestions and comments about our services. Here are some comments from other customers:

We needed a small batch of CNC parts on a tight deadline, and Olige came through for us. From the initial consultation to the final delivery, their team kept us updated at every step. The quality of the parts was exceptional, and they even provided valuable DFMA feedback that saved us time and costs during production. We will definitely be working with them again!

We had a complex component design with tight tolerances, and Olige’s multi-axis machining capabilities handled it with ease. The parts came out exactly as designed, with perfect dimensional accuracy. Their team was very responsive and made the entire process smooth from start to finish.

"Our company has partnered with Olige for several large-scale production runs, and their consistency is what sets them apart. They maintain the same high standards of quality whether we order 10 pieces or 1,000. Their team’s expertise in CNC milling and turning has been instrumental in meeting our production goals."

COMMON QUESTIONS

Most Popular Questions

Feel free to contact us if you have any questions.

Multi-axis CNC machining involves the movement of cutting tools along multiple axes (3-axis, 4-axis, and 5-axis). This allows us to create intricate geometries, reduces setup time, and improves surface finishes, making it ideal for complex parts.

We can machine a wide range of materials, including aluminum, stainless steel, titanium, brass, copper, plastics, and composites. If you have a specific material in mind, feel free to consult with us.

Yes, we provide free DFMA (Design for Manufacturing and Assembly) feedback to help optimize your designs for the CNC machining process. This ensures that your parts can be produced efficiently and cost-effectively.

You can request a quote by filling out the “Request a Quote” form on our website or contacting us directly via email or phone. Please provide your CAD files and any relevant specifications for an accurate quote.

Yes, we offer rapid prototyping to help you quickly create functional prototypes and validate your designs. Our CNC prototyping services deliver parts that match the material properties of final production components.

Our CNC machining processes can achieve tolerances as tight as ±0.005 mm depending on the complexity of the part and material used. We’ll discuss specific tolerances during the design phase to meet your project requirements.

We accept a variety of CAD file formats, including .STEP, .STL, .DWG, .DXF, IGES, and Zip. If you have a different format, let us know, and we’ll work to accommodate it.

Our typical response time for quotes is 24-48 hours. However, more complex projects may take slightly longer for thorough assessment.

Turnaround times depend on the complexity and volume of your order. Rapid prototypes can be produced in as little as 3-7 days, while batch production may take a few weeks. We provide estimated timelines during the consultation phase.

Yes, we provide global shipping services, delivering parts to clients worldwide. We work with reliable logistics partners to ensure that your components arrive safely and on time.

GET IN TOUCH

Whenever you need us, we’re here for you.

Our experienced team is ready to review your design and provide a competitive, customized solution that meets your exact specifications. Follow the simple steps below to request your quote:

No. 6, Zhanglu Street, Zhangge Community,

Fucheng Street, Longhua District, Shenzhen

Phone : +86 19925419493